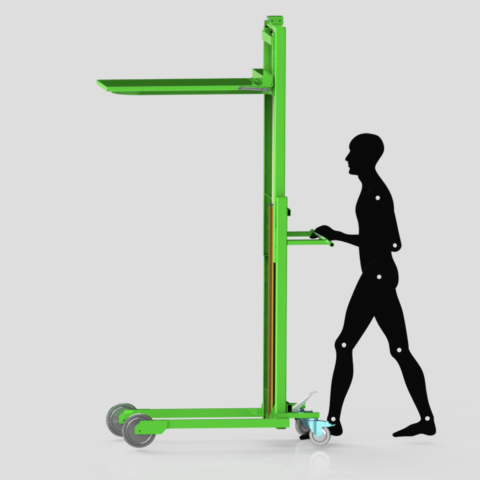

For smaller and satellite warehouse operations, manually operated lifters offer a significant cost saving over powered lifting equipment. In many cases, the use of our DuoPump manually powered equipment is faster and easier than a more expensive battery powered devices. Manually powered lifters and also much lighter and easier to move and can turn in narrow aisles safely and easily.

-

Detachable merchandising pallets are available for many of our lifters. These securely integrate with lifting and stacking equipment to enable bulk item transfer. The merchandising pallets can be left with stock in the warehouse or in the retail area.

-

Lifters can be designed to handle half pallets from either orientation. This half pallet lifter is used to handle semi-pallets upto 300kg in portrait for quick and efficient movement of stock.

-

Lifting to 2 metres with fast lift stacker. This product has an Articulated mast for compact size when fully lowered.

-

This lifter and stacker is designed to handle pallets and dollies. It has an optional deck fitted to allow handling of a variety of boxes and containers.

-

Lifters can be quickly raised to optimise picking height, and lowered for safe movement to goods out area.

-

Fast lift versions allow stacking and handling of goods up to 2 metres high.

-

Lifter Picking trolley designed for Australian returnable plastic containers, which operator workstation, litter bins, and operator terminal option.

-

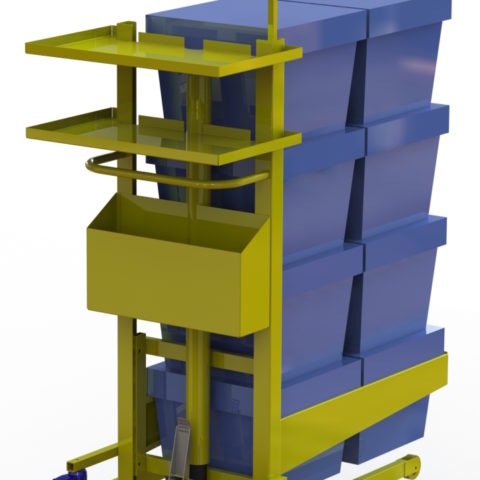

Dedicate plastic container handling equipment is ideal for picking and warehousing. These units can lift plastic containers directly from shelves or the floor without any manual handling.

-

Multple stacks of containers can be transferred to warehouse and then the lifter can be raised and lowered to ensure quick and safe shelf replenishment.