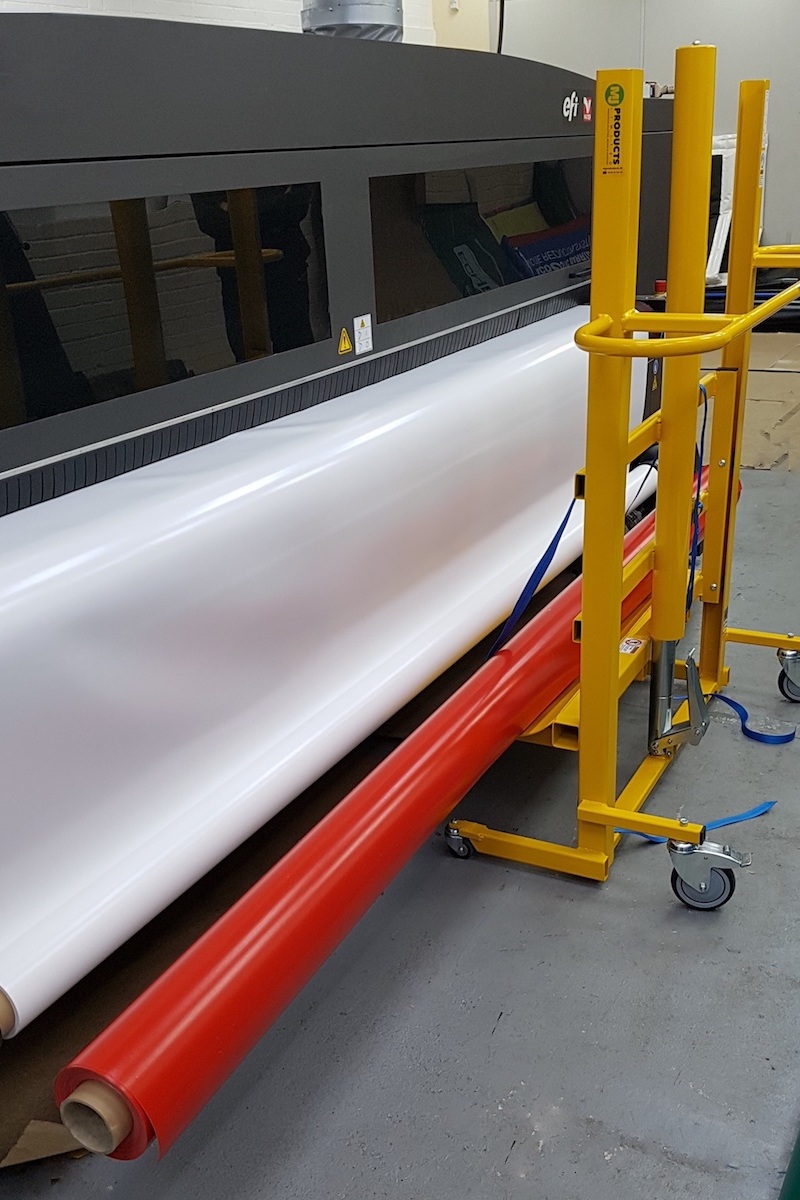

RL Series Roll Lifters are the optimum solution for handling cylindrical loads of all shapes and sizes, from fabrics and carpets to adhesive reels and label rolls.

Lifters for wide rolls feature a purpose design semi-circular platform and an integrated floor scoop to transfer rolls from ground level. Swivel castors on all 4 corners afford a wide wheel track for a higher stability and easy manoeuvrability in tight workspaces.

Lifters for label rolls and feed stock use a single central boom designed to fit inside standard 76mm or larger cardboard cores. Bearings on the boom allow rolls to slide seamlessly to and from machine spindles, dollies, cutting tables and other storage. The quick-release latch secures rolls during movement and allows smooth unloading at the destination.

Our optional purpose design RD1 roll dollies enable full and part-used rolls to be stored safely vertically. When not in used, the dollies can be stacked to save usable floor space.

RL series lifters are designed to work with existing machinery and allow materials to be presented to a production area or assembly line directly from the lifter, significantly reducing manual handling.

Applications for rolls lifters can include:

- Loading and unloading a label printing machine

- Handling for labels rolls and other narrow rolls using our boom system design

- Loading and unloading CNC fabric cutting machines for vinyl and other materials

- Handling rolls of carpets to and from storage with our high lift range

Because our devices are manually operated and lightweight, they can also be used in stores and other public areas, with reduced safety precautions when compared to electric powered devices.

All our lifting and handling products are designed and manufactured in the UK. Contact us with your application and we will recommend or develop an exacting solution for your requirements.