Printing of self adhesive labels involves lifting rolls of blank pre-cut label media into a printing process and finishing with customer graphics.

The rolls can be over 60kg in weight and difficult to handle safely.

M J Products was approached by Hine Labels, a specialist self adhesive label manufacturer in Rotherham.

Hine wanted a handling solution to the following specification.

- To remove the need to manual handling of rolls of labels

- To reduce damage to part rolls of labels when removed from printing and returned to stock

- To manoeuvre in compact areas alongside printing facilities.

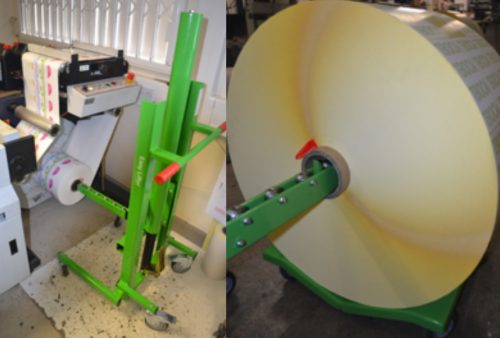

The solution : An M J Products Easylifter with 4 swivel wheels and a footprint to reach around label rolls, combined with purpose made V dollies to store stock safely in a vertical orientation to reduce damage to part used stock.

The Roll Lifter, model RL1, has a boom with integrated rollers to allow easy transfer of the labels to and from the machine, couple with a latch to prevent the rolls from rolling off the boom in transit.

Easy access into confined spaces allows loading onto printing processes that are close together.

“The Easy lifter is ideal for our operation. It enables us to load labels into our equipment safely and effortlessly. And we can safely store part used feed stock on the V dolly to prevent damage when laying over labels onto pallets.” William Hine, Managing Director, Hine Labels.

The RL1 Roll Lifter lifts upto 250kg, upto 800mm high using the DuoPump rapid lift technology. It is lightweight and easy to manoeuvre and doesn’t require batteries.

For more information email info@mjproducts.co.uk